In recent years, 3D printing technology has gained immense popularity and has revolutionized various industries. From manufacturing to healthcare, this innovative technology has the potential to reshape our world. However, understanding 3D printing technology can be quite daunting for beginners. With the aim to demystify this technology and provide you with a comprehensive guide, this article dives deep into the world of 3D printing.

Demystifying 3D Printing Technology

Before delving into the intricate details of 3D printing, it’s important to grasp the basics. 3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects from a digital design using layers of material. While this may sound futuristic, 3D printing has been around for several decades, steadily evolving and improving.

Understanding the basics of 3D printing is crucial as it forms the foundation for exploring the vast possibilities and applications of this technology.

Understanding the Basics of 3D Printing

At its core, 3D printing involves a process known as slicing, where a digital model is broken down into layer-by-layer instructions that the printer can understand. These instructions guide the printer to deposit material layer by layer, ultimately forming the final 3D object.

But how does the printer know where to deposit each layer of material? This is where the magic of 3D printing software comes into play. The software takes the digital model and slices it into hundreds or even thousands of thin layers, each with its own set of instructions for the printer. These instructions include details such as the path the printer’s nozzle should follow, the temperature at which the material should be extruded, and the speed at which the printer should move. It’s a delicate dance of precision and coordination, all orchestrated by the software.

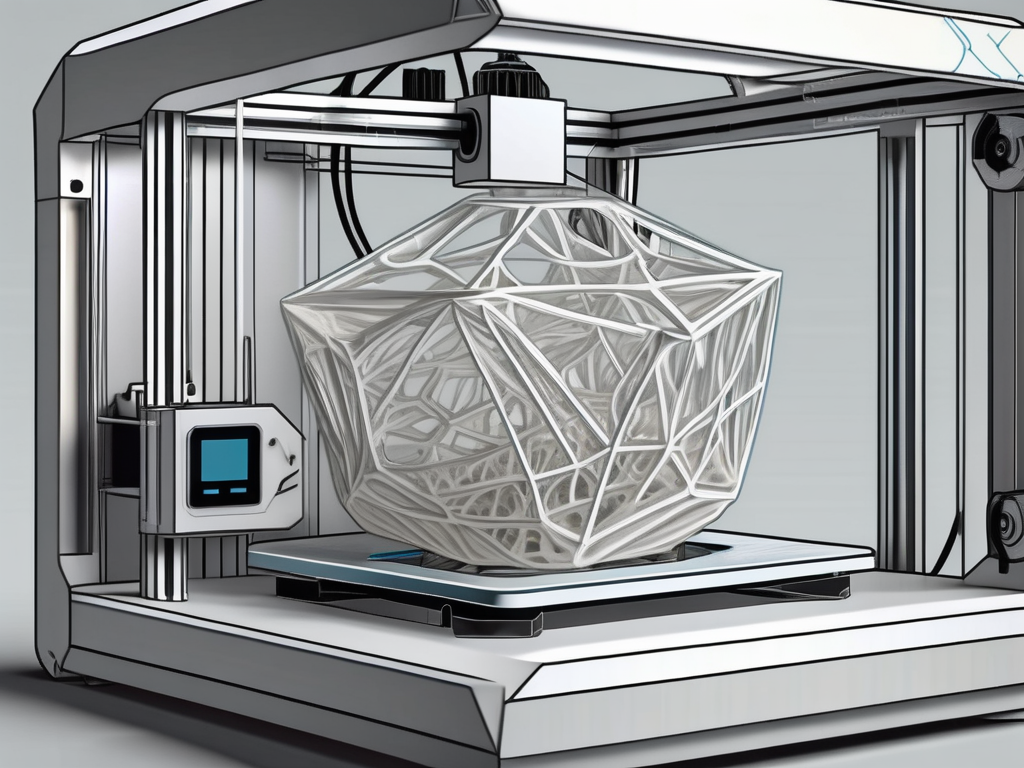

There are several types of 3D printers available, each operating on different principles. To truly grasp the technology, let’s explore some of the most common types of 3D printers.

Exploring the Different Types of 3D Printers

One of the most popular types of 3D printers is the Fused Deposition Modeling (FDM) printer. FDM printers work by melting a thermoplastic material and extruding it through a nozzle in layers to build the object. These printers are affordable, versatile, and widely used for various applications.

An alternative to FDM printers is the Stereolithography (SLA) printer. SLA printers use a different approach called photopolymerization, where liquid resin is cured layer by layer using ultraviolet light. This technology enables the production of highly detailed and smooth objects.

Besides FDM and SLA, there are other types of 3D printers such as Selective Laser Sintering (SLS), Digital Light Processing (DLP), and Binder Jetting printers. Each type offers unique benefits and is suitable for specific applications.

For example, SLS printers use a laser to selectively fuse powdered material, such as metal or nylon, layer by layer. This makes them ideal for creating complex and durable objects. On the other hand, DLP printers use a digital light projector to cure liquid resin, allowing for faster printing speeds and high-resolution prints.

Binder Jetting printers, on the other hand, use a liquid binding agent to selectively bond layers of powder together, resulting in full-color, highly detailed prints. These printers are often used in the field of architecture and design, where aesthetics and intricate details are of utmost importance.

As you can see, the world of 3D printing is vast and diverse, with each type of printer offering its own set of advantages and applications. Whether it’s creating prototypes, manufacturing custom parts, or even producing intricate works of art, 3D printing has revolutionized the way we bring our ideas to life.

A Closer Look at 3D Filament Printers

Within the realm of 3D printing, filament-based printers are widely adopted due to their accessibility and ease of use. These printers utilize a plastic filament, typically made of materials like PLA or ABS, which is melted and extruded through a nozzle to create the desired object.

One of the benefits of filament-based printers is the wide range of materials available. From the traditional PLA and ABS to more advanced materials like flexible filaments and carbon fiber composites, filament printers cater to various needs and requirements.

While filament printing is relatively straightforward, there are still challenges that users may encounter. In the next section, we will explore some expert tips and tricks to master the art of 3D printing.

Furthermore, the evolution of filament-based 3D printers has led to the development of dual-extruder systems. These systems allow for the simultaneous use of two different filaments during the printing process, enabling multi-color or multi-material prints. This advancement has opened up a new realm of possibilities for creators and designers, pushing the boundaries of what can be achieved with 3D printing technology.

Another noteworthy aspect of filament-based 3D printers is the importance of proper calibration. Ensuring that the printer’s settings are accurately calibrated can significantly impact the quality and success rate of prints. Factors such as nozzle temperature, bed leveling, and filament diameter consistency all play crucial roles in achieving precise and reliable prints. By fine-tuning these settings and regularly maintaining the printer, users can optimize their printing experience and achieve consistent results.

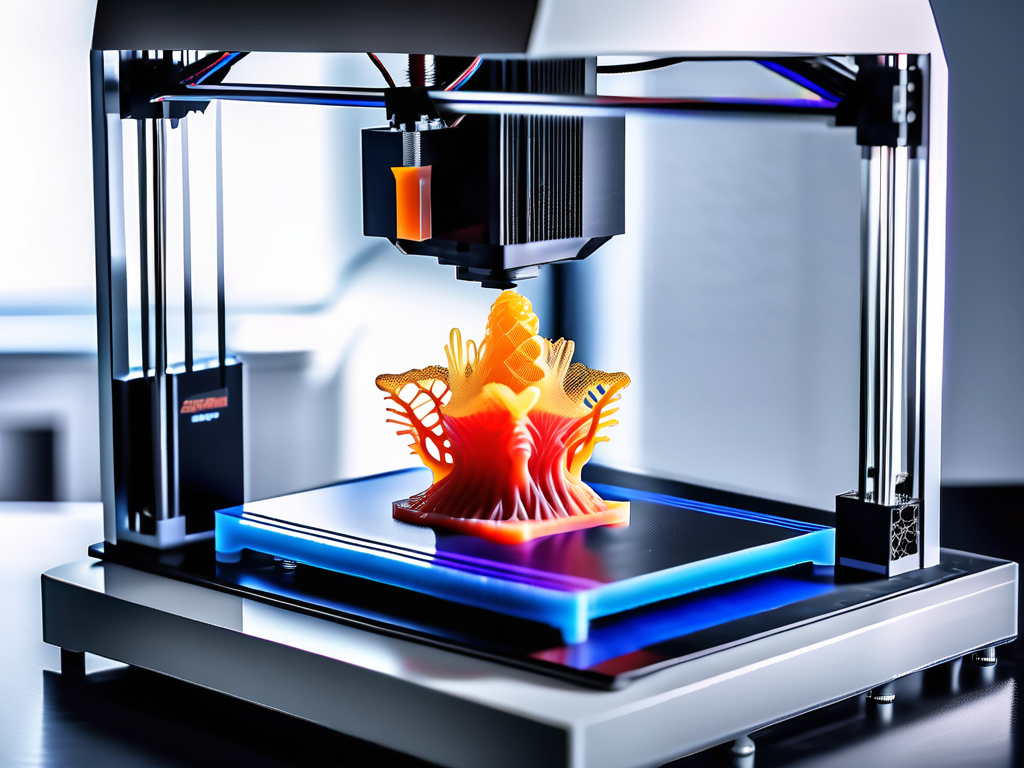

Exploring the World of 3D Resin Printers

As the demand for high-quality and precise prints increases, 3D resin printers have gained significant traction in the market. Unlike filament-based printers, resin printers use liquid photopolymer resin that is solidified layer by layer using ultraviolet light.

The use of liquid resin allows for the creation of highly detailed and intricate objects with smooth surfaces. This makes resin printers ideal for applications such as jewelry making, dental models, and prototyping of small mechanical parts.

However, it’s worth mentioning that resin printing comes with its own set of challenges. The handling of liquid resin, post-processing steps, and the need for proper ventilation are some factors that require attention. Taking necessary precautions and following best practices is essential for a successful printing experience.

One of the key advantages of 3D resin printers is their ability to produce objects with incredibly fine details. The layer height in resin printing can go as low as 25 microns, resulting in smooth surfaces and intricate designs that are hard to achieve with traditional FDM printers. This level of detail makes resin printers a popular choice for artists, designers, and engineers who require precision in their prototypes or final products.

Another aspect to consider when delving into the world of resin printing is the variety of resin materials available. From standard resins suitable for general use to specialized resins with properties like flexibility, toughness, or biocompatibility, the options are vast. Each type of resin has its own curing requirements and post-processing techniques, adding another layer of complexity to the resin printing process.

Mastering 3D Printing: Expert Tips and Tricks

While 3D printing technology has come a long way, it’s not without its fair share of challenges. From print failures to inconsistent results, troubleshooting common issues is part of the learning process. Let’s take a closer look at some of the most common problems encountered in 3D printing and how to overcome them.

Troubleshooting Common 3D Printing Issues

Print failures, such as warping and layer shifting, are some of the most frustrating problems faced by 3D printing enthusiasts. These issues can be caused by various factors, including incorrect printer settings, inadequate bed adhesion, or even hardware malfunctions. By understanding the root causes and implementing appropriate solutions, you can significantly improve your print quality.

Maximizing Efficiency in 3D Printing Projects

While troubleshooting is essential, prevention is always better than cure. To make the most of your 3D printing projects, it’s crucial to optimize your workflow and maximize efficiency. From choosing the right slicing software and utilizing support structures effectively to optimizing print settings for speed and quality, various strategies can help enhance your overall printing experience.

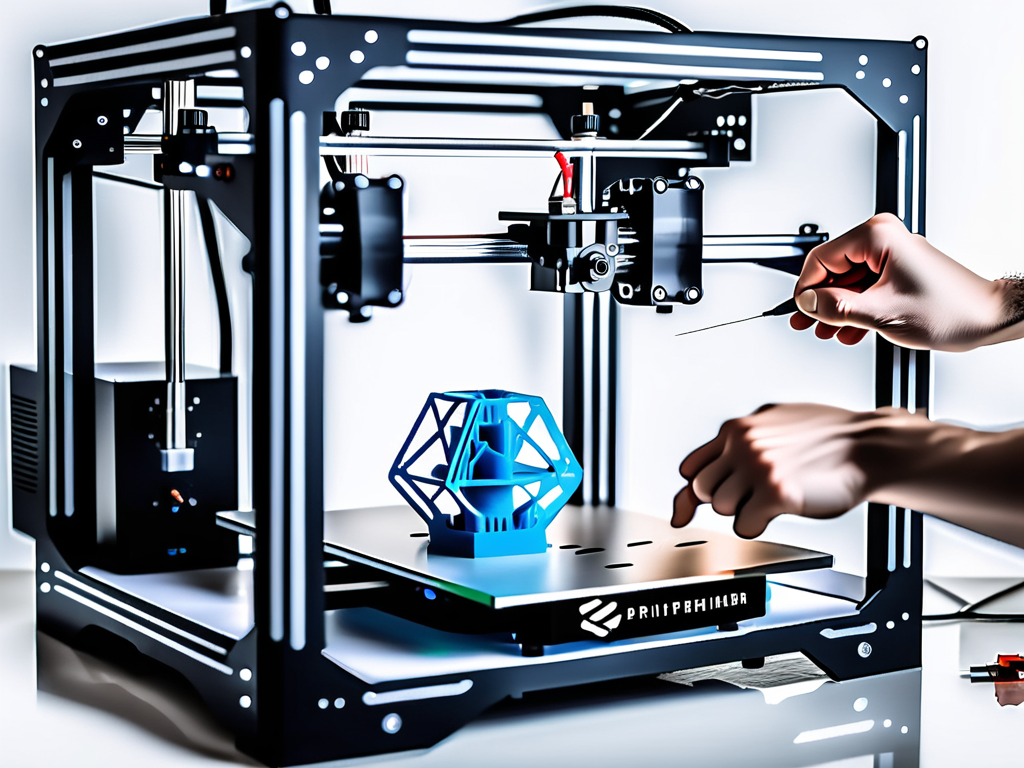

Setting Up Your 3D Printer Made Easy

After gaining a fundamental understanding of 3D printing technology and exploring the different types of printers, it’s time to put your knowledge into action. Setting up your 3D printer may initially seem daunting, but with the right approach, it can be a straightforward process.

Step-by-Step Guide to Assembling Your 3D Printer

Each 3D printer comes with its own assembly instructions, but the general process involves connecting various components, such as the frame, motors, and extruder. Following a step-by-step guide and referring to the manufacturer’s instructions can simplify the assembly process, ensuring your printer is ready for the next stage.

Calibrating Your 3D Printer for Optimal Performance

Calibration is a critical step to ensure your printer operates at its best. It involves adjusting parameters such as the nozzle height, bed leveling, and extrusion flow rate. Proper calibration is essential for achieving accurate prints and preventing potential issues during the printing process.

Staying Updated: The Latest in 3D Printing Innovations

As technology continues to evolve, so does the world of 3D printing. Staying updated with the latest innovations and trends is crucial for enthusiasts and professionals alike. From advancements in materials and software to new techniques and applications, the 3D printing landscape is constantly expanding and presenting exciting opportunities.

Whether you’re an artist, engineer, or hobbyist, understanding the potential of 3D printing technology can open up a world of possibilities. By continually staying informed and actively participating in the community, you can unlock the true potential of this groundbreaking technology.

Conclusion

In conclusion, 3D printing technology is a captivating field with unlimited potential. By understanding the basics of 3D printing, exploring different types of printers, and mastering the art through expert tips and tricks, you can unlock the true power of this technology. Setting up and calibrating your printer is crucial for successful prints, and staying updated with the latest innovations will keep you at the forefront of this cutting-edge industry. So, embark on your 3D printing journey, explore new frontiers, and let your creativity soar!

If you would like to learn more about what we can offer in terms of Computer Repair Services please click the link below